Taking care of the environment is in our DNA. Through innovations and contentious process improvements, we focus on new and greener solutions for our customers. In-line with this commitment, our Proviflow division is offering a range of smart and innovative solutions to help improve the sustainability goals of our partners in the industrial refrigeration, DATA, HVAC, process cooling, manufacturing, power, geothermal and solar industries.

There are many hurdles in this endeavor. Across the board, we are seeing updated government regulations that require our partners to expand their knowledge base, procedures, and safety protocols to ensure compliance.

At Proviflow, we need to invest not only in innovative products, but also in the transfer of knowledge. As experts in ‘the chemistry’ of heat transfer fluids, we are also educators, focused on helping industries transition to ‘green’ regulations faster as a consultative resource.

We have embraced ‘green’ initiatives to curb the use of F-gases at a global level.

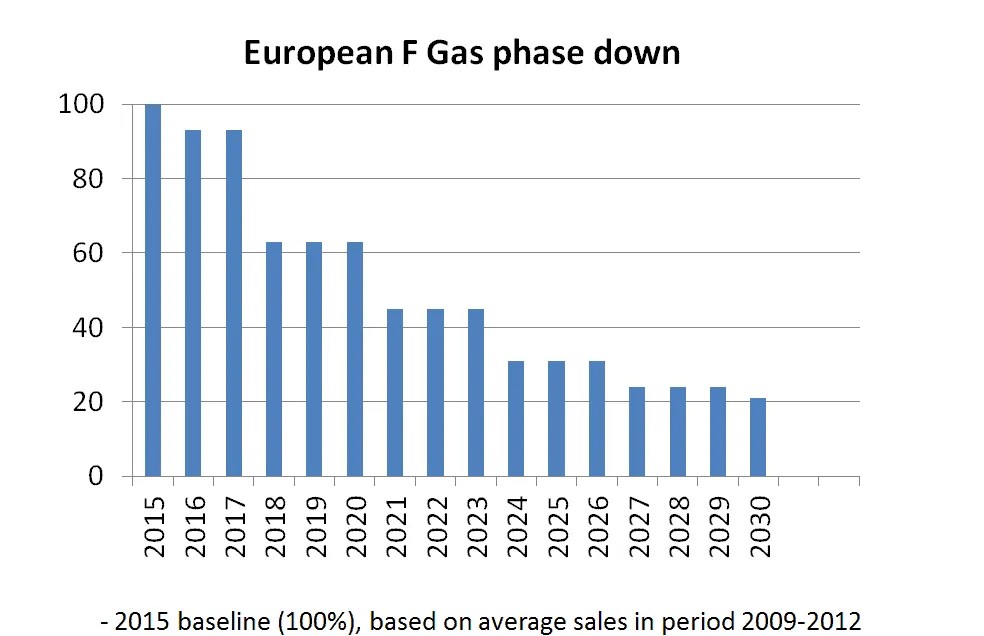

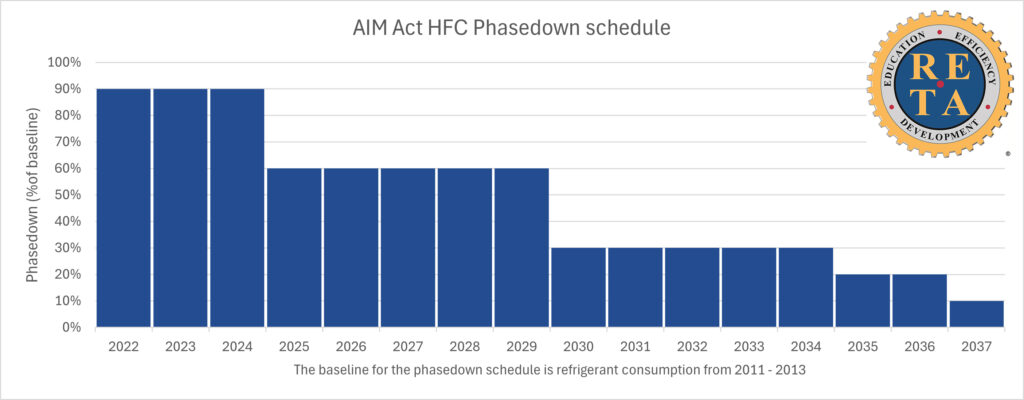

F-gas regulations are being implemented internationally. In Europe, under the “Green Deal” and in the USA under the AIM act. These initiatives are strikingly similar only differing in implementation scale by region. An overview:

The European Green Deal is a bold initiative aiming to make Europe the first climate-neutral continent by 2050. A critical component of this plan is the reduction of fluorinated gases (F-gases) in the refrigeration sector, known for their high global warming potential.

Phase-Down of F-Gases

Promotion of Alternatives

Strengthened Regulations

The American Innovation and Manufacturing (AIM) Act is a landmark initiative aimed at reducing the use of hydrofluorocarbons (HFCs) in the refrigeration industry, a critical step towards combating climate change and promoting environmental sustainability.

Phasedown of HFCs

Promotion of Safer Alternatives

Regulatory Measures

Glycol is the most promising cold carrier in the push for more sustainable refrigeration installations due to its unique human health and environmentally friendly properties. As a secondary refrigerant, glycol is most often used in tandem with ammonia as the primary refrigerant, however, alternative primary refrigerant such as Co2 are becoming more popular for safety reasons.

In an installation with a dual refrigeration circuit, the burden load is spread across both the primary and secondary process loops. The primary refrigerant and is responsible for generating and maintaining the intended process temperature while the secondary refrigerant is used to transport this process temperature to the production site in a safe manner.

The main advantage of this configuration being that less primary refrigerant is needed while achieving the same result as an F-gas cooled system. The secondary circuit utilizing a more environmentally friendly Heat Transfer Fluid ‘glycol’ mitigating potential environmental and human health impact. This solution offers many benefits in the international green initiative!

In the fast-evolving world of HVAC and refrigeration, staying ahead requires more than just keeping up with technology—it demands mastery. That’s why comprehensive and expedited training for installers in the use of secondary cooling systems with glycol is essential. Here’s how better and faster training can revolutionize your installation processes and elevate your professional capabilities.

With superior training, installers become adept at handling secondary cooling systems with glycol, which translates to faster installation times. Efficiency in installation not only reduces labor costs but also minimizes downtime for clients, leading to higher customer satisfaction. Well-trained installers can complete projects swiftly without compromising on quality, ensuring timely project delivery.

Secondary cooling systems utilizing glycol offer numerous advantages, including improved temperature control and reduced risk of freezing in low-temperature applications. Proper training ensures that installers understand the intricacies of these systems, leading to optimal performance. Knowledgeable installers can fine-tune systems for maximum efficiency, resulting in energy savings and prolonged equipment life.

Glycol systems, while highly effective, require careful handling to ensure safety and compliance with industry standards. Comprehensive training programs emphasize the importance of safety protocols, teaching installers how to manage and mitigate potential hazards. This focus on safety not only protects the installers but also ensures the safety of end-users and the environment.

The HVAC and refrigeration industries are continually advancing, with new technologies and methods emerging regularly. Better and faster training ensures that installers are always up-to-date with the latest advancements in secondary cooling systems using glycol. This continuous education allows you to offer cutting-edge solutions to your clients, keeping you at the forefront of the industry.

training as key for a faster switch to greener alternatives

Investing in better and faster training for installing glycol secondary cooling systems is not only keeping pace with the industry, it is also the way to accelerate the pace for more sustainable cooling.

By better training installers and engineers in new technology, they will be able to choose more sustainable installations with confidence. In this way, we are accelerating the exit of harmful refrigerant gases and replacing them with more sustainable solutions.

Our website makes use of cookies and similar techniques to ensure you get the best experience.

Via our cookie policy we like to inform you. Please click OK to continue.