The Proviflow range of heat transfer fluids are formulated using inhibitors and have been designed to cope with the most demanding of conditions in heating and cooling systems. Our fluids are designed for an excellent freeze point suppression and an enhanced protection against corrosion, hard water scaling and bacterial growth.

Proviflow L and Proviflow Neo are formulated using OAT (Organic Acid Technology) inhibitors and have been designed to cope with the most demanding of conditions. They can be used in a wide variety of applications and offer excellent freeze point suppression as well as enhanced protection against corrosion, hard water scaling and bacterial growth.

Proviflow L and Proviflow Neo are free from Phosphates, Nitrites, primary/secondary Amines, Silicates and Borates.

Proviflow FG is an MPG based heat transfer fluid with a specially formulated inhibitor package for use in food and drink applications, containing exclusively FDA approved components. Proviflow FG has been registered by US NSF and classified as a HT1 heat transfer fluid for potential incidental food contact. Due to its low acute oral toxicity, Proviflow FG can be used in a wide range of food and beverage cooling applications where safety and certainty matter.

All Proviflow fluids are tested to and exceed the ASTM1384-05 corrosion test standard. The range also contains a highly-advanced reserve alkalinity additive. This ensures a longer and more efficient working life, limited disruption to processes, reduced maintenance costs and ultimately an improved return on capital employed. All Proviflow products are designed and manufactured to the highest standards to give the end-user greater peace

of mind in the knowledge that every product offers a long and efficient working life. In order to ensure this, we recommend following our best practice advice.

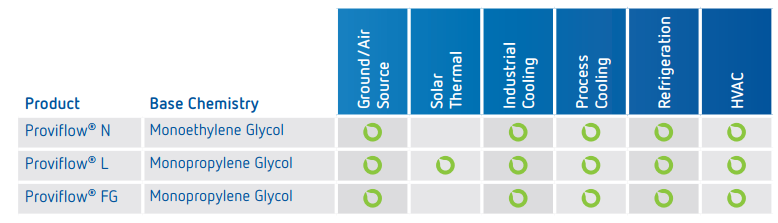

PRODUCT APPLICATION TABLE

In solar thermal applications, Proviflow L has demonstrated excellent, long-term thermal stability at temperatures of up to 160˚C. It can also withstand degradation at stagnation temperatures approaching 200˚C for short periods of time. The longevity of a solar thermal heat transfer fluid is dependent on numerous variables, some of which are not fluid related. In order to ensure that you obtain the maximum possible lifespan from your fluid, you must ensure that stagnation events are kept to a minimum. Any excessive and unnecessary periods of fluid stagnation will lead to the degradation of any glycol-based heat transfer fluid.

All Proviflow products are concentrated fluids and must be diluted before use.

The values in the table are the freeze points for varying levels of dilution of Proviflow products.

DILUTION TABLES

Please refer to the level of freeze protection and freeze point required as indicated by the system manufacturer. Freeze points are determined based on the ASTM D1177 standard.

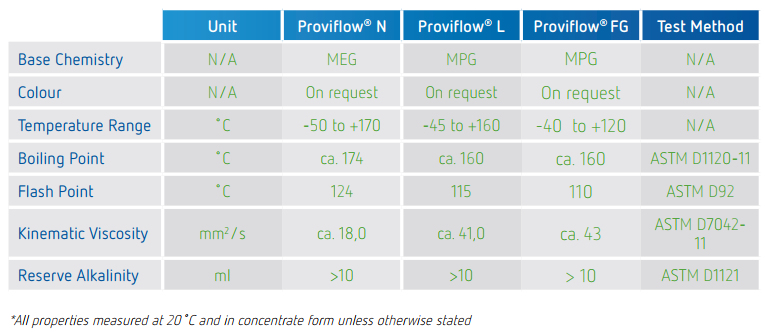

SPECIFICATIONS

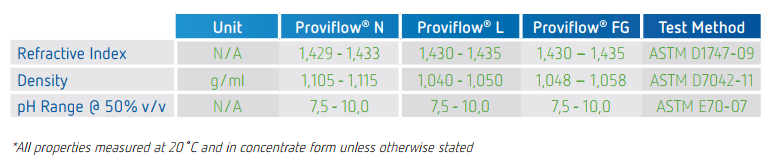

PHYSICAL PROPERTIES

heat pumps

Our website makes use of cookies and similar techniques to ensure you get the best experience.

Via our cookie policy we like to inform you. Please click OK to continue.